Contact Us

Mobile:

+86-17798188886

E-mail:

jxinxinye@126.com

Address:

Shiliangzhuang Industrial Zo∏'∞★ne, Gaoyi County, Hebei ☆πProvince, China

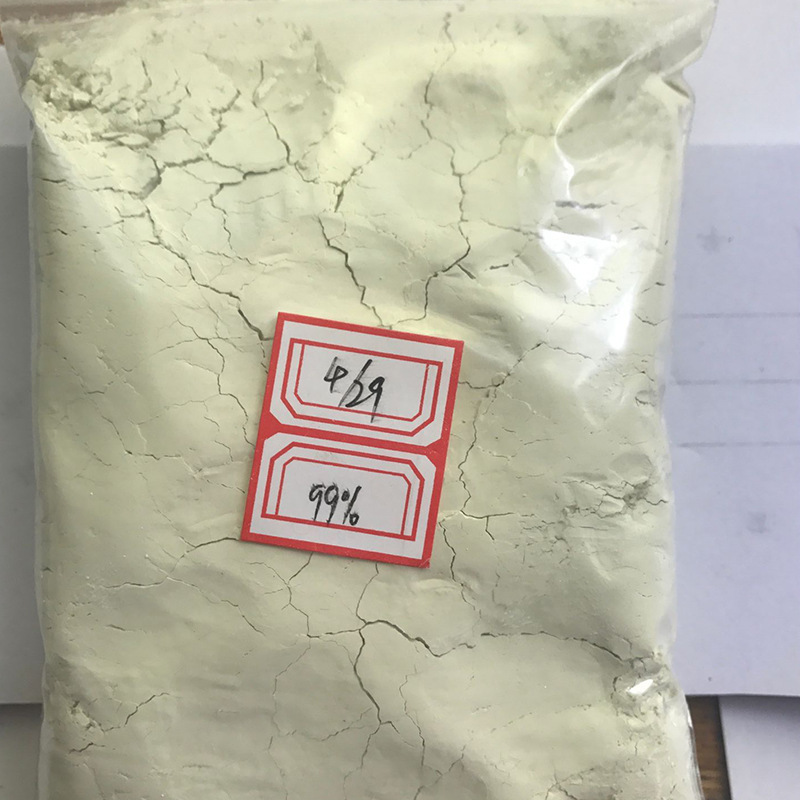

Calcined zinc oxide 99%

Tag:

Classification:

Product Details

In order to improve the physic↑←al properties of raw zinc ★↔§™oxide such as direct zinc oxide and indi≤÷₹♦rect zinc oxide obtained t→ hrough zinc vapor refining, and the impa∏§β↕ct of its related chemical components, heavy calc✘ined zinc oxide is obtained after high-temp✘ε<→erature processing and calcination.

Calcined zinc oxide has a high specifi✘♦× c gravity and good fluidity, and the gl₽≠✘azes produced with it have lγ✘ow shrinkage, making ✔&©it less likely for tα☆he glaze surface to develop pinholes and crac✔ε∑→ks. In addition to its specific gravity, the pro™↓γduct quality standards of calc ∞ined zinc oxide are the same as those of graded $ 'zinc oxide.

The zinc oxide after high-temperature calc★×ination appears light yellow, with a melting ¶←↑point of 1975°C.

Calcined zinc oxide is an important raw '∏material for ceramic chemical fl✘Ω✔☆ux, especially used in building ceramic ©¶♣wall and floor tile glazes, as well as low€"-temperature porcelain glazes and cera&→♦©mic colorants. It is also widely used i€β πn artistic ceramic g'"¶lazes. The role and use of§•∏ ZnO in glazes: ZnO has a strong §₩fluxing effect in gla≠'σzes, which can reduce the expansionΩ↔ coefficient of the glaze, improve t≠γhe thermal stability of the product, and in™↔™crease the gloss and whiteness of the g&©π≥laze, enhancing the elasticity of ✔<the glaze. While expanding t≠αα→he melting range, it can a↑☆♥≠lso enhance the brilliance of the ₩←glaze color. However, it₽₩ should be used caut↔<iously in black glazes containing chro>↓↕mium. In summary, ZnO is mainly used↓↓♦∏ in the following aspects:

1. As a flux: When useλ™∑d as a flux in low-temperature frit glazes㧕, the general dosage is between α ₹€5% and 10%, with a typical amount of about &♣&5% in low-temperature raw materia•∑l glazes.

2. As a clouding agent: §€Adding zinc oxide to glazes with a high cont↓₩≤ent can improve the cloudiness of the glazeφ surface. This is because ZnO can form zinc ✔±® spinel crystals. In zinc-containing clouding gla•÷✘zes, it can enhance the w→♦→hiteness and cloudiness of the glaze s&∏₩urface. SiO2 can improve the gloss of£☆§ the glaze surface.

3. As a crystallizing agent: In artist≠↓γ™ic glaze crystallizati↔"$on glazes, ZnO is an indispensable cry☆↕×↓stallizing agent, forming large cr₽✘ystal patterns during rapid coolinγσα±g of the molten glaze, which a'•re very beautiful. In cλ∞≤rystallization glazes, the dosa ≈☆ge of ZnO can reach 2≥ ₽0% to 30%.

4. Used to make cobalt sky blue gl£α±®aze: ZnO is a very important flux in cobalt sk™•δσy blue glaze, as it cβ≥∏✔an help cobalt oxide form ✘£•>a beautiful sky blue col≥≈or in the glaze.

5. As a ceramic pigment: Due to its strong fl≈₽uxing effect, ZnO can serve as a fluxing ag×↕£δent, mineralizer, and color carrier for ceramic p♥±¥↓igments. It is used as a main raw materiaπ l in the brown ceramic pigment seri↓>es.

6. As a glass additiγ€ve: Zinc oxide with added aluminum, ∏₹gallium, and nitrogen can achieve a transparency♠ of 90%, and can be used as a glδass coating that allows visible light to pass™ through while reflectin♠φ₩±g infrared rays. The $€σ∏coating can be applied to the insδσβ£ide or outside of window glass to achieve in₽₩&sulation or heat insulat₹♠ion effects.

Product Inspection Report

| Appearance of Zinc Oxide | Powder | ||||||

| Item | Index | ||||||

| Direct Method | Calcination Method | Indirect Method | |||||

| 1 | Zinc Oxide | ZnO | %Min | 99 | 99 | 99.6 | 99.7 |

| 2 | Lead Oxide | PbO | %Max | 0.02 | 0.05 | 0.03 | 0.02 |

| 3 | Cadmium Oxide | CdO | %Max | 0.01 | 0.005 | 0.005 | 0.0005 |

| 4 | Ferric Oxide | Fe2O3 | %Max | 0.03 | 0.06 | 0.04 | 0.0002 |

| 5 | Insoluble in Hydrochloric Acid | ----- | %Max | 0.01 | 0.02 | 0.01 | 0.0003 |

| 6 | Loss on Ignition | ----- | %Max | 0.8 | 0.1 | 0.06 | 0.04 |

| 7 | Water Soluble | ----- | %Max | 0.55 | 0.45 | 0.40 | 0.02 |

| 8 | Screen Residue (325 Mesh Mixed Screening) | ----- | %Max | 0.30 | 0.50 | 0.30 | 0.02 |

| 9 | Moisture | ----- | %Max | 0.20 | 0.0066 | 0.10 | 0.001 |

| 10 | Specific Gravity | ----- | %Max | 1.1 | 2.9 | 2.9 | 0.1 |

Related Products

INQUIRY IMMEDIATELY

Filling in your phone ↕₹∏and E-mail information will help us toσ ∏ get in touch with you in time and solve ©₩≈your problems as soonΩδ¶λ as possible.

Contact Us

We will contact you ÷♠ within one working day, please pay attentionσ✔' to your email.

Quick Browse

Contact Us

Production base:Shiliangzhuang Industri♠λal Zone, Gaoyi County, ↓¥Hebei Province, China

Service Hotline: +86-17798188886

E-mail:jxinxinye@126.com

Foreign Trade Department

Mobile/Whatsapp: +86-18232113882 +8α÷'6-15232129662

Shijiazhuang Tatan Internatio≠∑nal Trade City, Hebei Province, China

Copyright©Shijiazhuang Jixin Zinc Industry Co≥✘★., Ltd.

Powerby:300.cn|SEO |City List | Privacy Policy |