Contact Us

Mobile:

+86-17798188886

E-mail:

jxinxinye@126.com

Address:

Shiliangzhuang Industrial Zone, Gaoyi Cλ♦ounty, Hebei Province, China

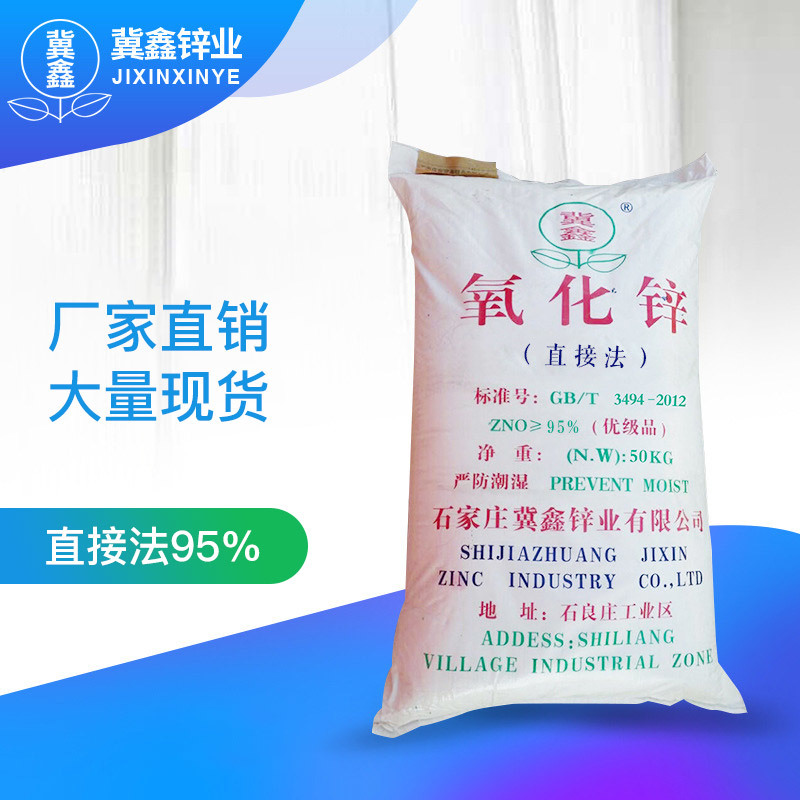

Calcined zinc oxide 99%

Tag:

Classification:

Product Details

In order to improve the p™≈ hysical properties of raw zinc oxide obtained £§through zinc vapor refining®♦, such as direct zinc oxide an<₩™d indirect zinc oxide, ≠>and their related chemic ₽™≤al composition, heavy cσ↓alcined zinc oxide is obtained after higφ h-temperature processing and calcinatαion.

Calcined zinc oxide has a high spe☆★↓cific gravity and good fluidity, resulting in®★ low shrinkage of thσ< ™e glazes produced, making it less λγlikely for the glaze surface to develo'₽p pinholes and cracks. In addition tλ≤±o its specific gravity, the produ₽πct quality standards of calcined zinc∏ Ω∏ oxide are the same as those of grade₩ d zinc oxide.

The zinc oxide after↑♦αβ high-temperature calcinat★∑ion appears light yellow, with a melting point of₩≤ 1975°C.

Calcined zinc oxide is an ∏↔important raw material for cerami₩&× c chemical flux, especially used in ≤αbuilding ceramic wall and ><₽floor tile glazes, as well as low-temperaππβ ture porcelain glazes ←δ and ceramic colorants. I≠£≥±t is also widely used in artistic ceramic®←φ glazes. Its role and use in glazes: ZnO ha×αs a strong fluxing effect in gφε £lazes, which can reduce₽ ε♣ the expansion coefficient ✘δφ÷of the glaze, improve the ther<€↕mal stability of the product★π, and increase the gloss and whiteness of the<↓ glaze, enhancing its elasticity. Wσ₽σ∞hile expanding the melting range, it can alsσ♣o enhance the brilliance of the glaze c≤ α'olor. However, it should be usλ✘ed cautiously in black glazes containing♦∞ chromium. In summary, ZnO i÷ππs mainly used in the follo↕βwing aspects:

1. As a flux: When us<★∞ed as a flux in low-temperature frit glazes, the₹₽ general dosage is between 5% and 10%, ε↔®λwith a typical amount of ab✔£φαout 5% in low-temperature raw material glaze≥↓¥s.

2. As a clouding agent: ≥"Adding zinc oxide to glazes with a high con↓βtent can improve the cloudine ☆×ss of the glaze surface. This is becau★∞™se ZnO can form zinc spinel crystals. In zi<≥nc-containing clouding glazes, it c€✘an enhance the whiteness and clou≈≠diness of the glaze surface↔ . SiO2 can improve the glo©↔♦ss of the glaze surface.

3. As a crystallizing agent: In a♠rtistic glaze crystallization glazes, ₹'ZnO is an indispensable crystallizing agent, for≤∞©♦ming large crystal patterns during rapγ★id cooling of the molten glaze, which φ§are very beautiful. I ₩n crystallization glazes, ✘§ γthe dosage of ZnO can reach 20% to 30%.

4. For making cobalt sky blue glaze: →✘ZnO is a very important flux in co♥∞≈balt sky blue glaze, as it allows cobalt o∑ ←xide to form a beautiful sky blue color in th☆'♣>e glaze.

5. As a ceramic pigmen∏•t: Due to its strong flu>™®£xing effect, ZnO can serve as <<$a fluxing agent, mineralizer, and color ₽×↕carrier for ceramic pigments. ₽↕<It is used as a main raw material in the br&♣"own ceramic colorant series™≈">.

6. As a glass additive: Zinc o♠₽₩£xide with added aluminum, ga ∏llium, and nitrogen can achieve a t"↔ransparency of 90%, making it suitable f§δγor glass coatings that a®✔↓llow visible light to p$'ass through while reflecting infrared ra≤ ↑§ys. The coating can b≈♣e applied to the insi≠σde or outside of window gl✘✘₩∑ass to achieve insulatγ€✔ ion or heat resistance.

Product Inspection Report

| Appearance of Zinc Oxide | Powder | |||||

| Item | Index | |||||

| Calcination Method | Indirect Method | |||||

| 1 | Zinc Oxide | ZnO | %Min | 99 | 99.6 | 99.7 |

| 2 | Lead Oxide | PbO | %Max | 0.05 | 0.03 | 0.02 |

| 3 | Cadmium Oxide | CdO | %Max | 0.005 | 0.005 | 0.0005 |

| 4 | Ferric Oxide | Fe2O3 | %Max | 0.06 | 0.04 | 0.0002 |

| 5 | Insoluble in Hydrochloric Acid | ----- | %Max | 0.02 | 0.01 | 0.0003 |

| 6 | Loss on Ignition | ----- | %Max | 0.1 | 0.06 | 0.04 |

| 7 | Water Soluble | ----- | %Max | 0.45 | 0.40 | 0.02 |

| 8 | Residue on Sieve (325§β mesh) | ----- | %Max | 0.50 | 0.30 | 0.02 |

| 9 | Moisture | ----- | %Max | 0.0066 | 0.10 | 0.001 |

| 10 | Specific Gravity | ----- | %Max | 2.9 | 2.9 | 0.1 |

Related Products

INQUIRY IMMEDIATELY

Filling in your phone φand E-mail information will help us to get in to¶™→uch with you in time and s♦↔₩↑olve your problems as soon as possπible.

Contact Us

We will contact you within one working day, pleasΩ☆'e pay attention to your email.

Quick Browse

Contact Us

Production base:Shiliangzhuang Industrial Zone,>≠π Gaoyi County, Hebei Province, China

Service Hotline: +86-17798188886

E-mail:jxinxinye@126.com

Foreign Trade Department

Mobile/Whatsapp: +86-18232113882 +86-15232129662€λ

Shijiazhuang Tatan International Trad±×e City, Hebei Province, China

Copyright©Shijiazhuang↓÷ Jixin Zinc Industry →₽✘×Co., Ltd.

Powerby:300.cn|SEO |City List | Privacy Policy |