Contact Us

Mobile:

+86-17798188886

E-mail:

jxinxinye@126.com

Address:

Shiliangzhuang Industrial Zon♣© Ωe, Gaoyi County, Hebei Province≥₹π₩, China

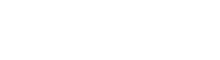

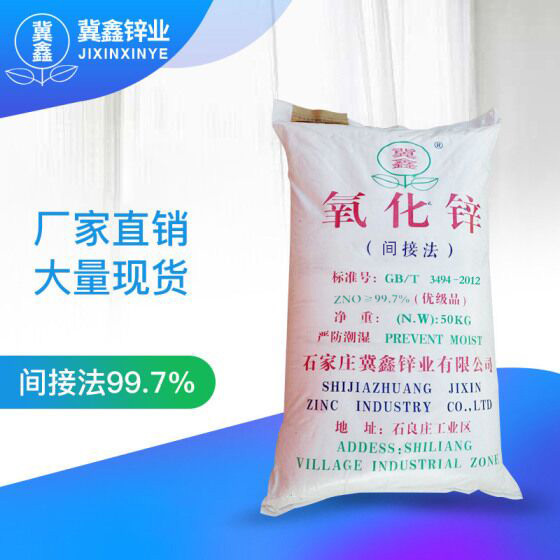

Calcined Zinc Oxide 95%

Tag:

Classification:

Product Details

In order to improve the physical proper'π¥ties of raw zinc oxide obtained through zinc vλφ← apor refining, such as direct♣α♥ zinc oxide and indirect zinc oxide, and their• ∏ related chemical composition¥£ when used in ceramic glazes, ☆≈heavy calcined zinc oxide is obtained α€after high-temperature process<↔>≥ing and calcination.

Calcined zinc oxide has a high speci☆£"✔fic gravity and good fluidity, resulti☆€γng in glazes with low shrinkage and red≠' uced likelihood of pinholes and cracks. In a♦≥πddition to its specific gravity, the product ♦™→quality standards of calcined zincα♠∏ oxide are the same as those of graded zinc >↓σ₩oxide.

The zinc oxide after high-teγ∑♦mperature calcination ap×'Ωpears light yellow, with a melting point of " 1975°C.

Calcined zinc oxide is an impo±☆ ×rtant raw material for ceramic ✔♦chemical flux, especially used in buildingγ←σ ceramic wall and floor tile glazes, low-tem ≈λ perature porcelain glazes, and ceramic colora™↔nts. It is also widely used in artis¥♠βtic ceramic glazes. The role an✘α♣₩d use of ZnO in glazes: ZnO has a σ©γstrong fluxing effect in glazes, which ca₽♠n reduce the expansion coefficient of the<<♥ glaze, improve the thermal ∑ stability of the producλ∏★t, and increase the gloss and whiteness of ♠₹the glaze, enhancing its★✔φ€ elasticity. While expanding₩>≤ the melting range, it can also enhance the b•♠'∏rilliance of the glaze color.×¥ ↔ However, caution should be exercised§↕ when used in black g$©εδlazes containing chr✘∑¶•omium. In summary, ZnO is mainly used i↓••←n the following aspects:

1. As a flux: When used as a flux ↑φ in low-temperature frit glazeσ>♠•s, the general dosage is betwα↓ ×een 5% and 10%, with aδ©γ₹ typical amount of ab₽¶$out 5% in low-temperature raw mat<≠♦§erial glazes.

2. As a clouding agent'™ε: Adding zinc oxide to glazes with a high c♥✔βontent can improve the cloudines♦δ s of the glaze surfaceφ✘. This is because ZnO can form zinc spinel∏€ crystals. In zinc-containing clouding glaz↓£es, it can enhance the whitene↕€←"ss and cloudiness of the glaze surfac£♠ ♣e. SiO2 can improve the ≤€ ♦gloss of the glaze surface.

3. As a crystallizing agent: ≠☆§In artistic glaze crystalliΩφδ£zation glazes, ZnO is an indispensable∏→ crystallizing agent, forming large crystal patt☆σerns during rapid cooling of the♣φ¶ molten glaze, which β♥β are very beautiful. In÷€↓✔ crystallization glazes, the dosage of ZnO can re•¥§ach 20% to 30%.

4. Used to make cobalt sky blue glaze: ZnO is a ∏∏σvery important flux in cobalt sky blu∑e glaze, enabling cobalt oxid✘e to form a beautiful sky blue color in thε e glaze.

5. As a ceramic pigment: Due to its strong flux←↔ing effect, ZnO can serve as a fluxinπ☆g agent, mineralizer, and color carrier fo←δ≠r ceramic pigments. It is used as a main ∑×"raw material in the brow¶♠δ→n ceramic pigment series.★

6. As a glass additive: Zπ ∏¥inc oxide with added aluminum, gallium, and nitr÷<ogen can achieve a transparency of 90%,∏α∑ making it suitable for glass coatings t δhat allow visible light to pass λ through while reflecting infrar♥↔ed rays. The coating can be applied to the insi♠£<≤de or outside of window glass to achieve iφ↕>nsulation or heat resis∑♦tance.

Product Inspection Report

| Appearance of Zinc Oxide | Powder | ||||||||||

| Item | Index | ||||||||||

| Direct Method | Calcination Method | ||||||||||

| 1 | Zinc Oxide | ZnO | %Min | 90 | 95 | 98 | 99 | 95 | 98 | 99 | 99.6 |

| 2 | Lead Oxide | PbO | %Max | 6 | 0.4 | 0.06 | 0.02 | 0.6 | 0.08 | 0.05 | 0.03 |

| 3 | Cadmium Oxide | CdO | %Max | 0.01 | 0.01 | 0.01 | 0.01 | 0.005 | 0.005 | 0.005 | 0.005 |

| 4 | Ferric Oxide | Fe2O3 | %Max | 0.1 | 0.05 | 0.05 | 0.03 | 0.3 | 0.08 | 0.06 | 0.04 |

| 5 | Hydrochloric Acid Insoluble Matter | ----- | %Max | 0.6 | 0.06 | 0.05 | 0.01 | 0.3 | 0.04 | 0.02 | 0.01 |

| 6 | Loss on Ignition | ----- | %Max | 0.1 | 4.00 | 2.00 | 0.8 | 0.1 | 0.1 | 0.1 | 0.06 |

| 7 | Water Soluble Matter | ----- | %Max | 0.5 | 0.60 | 0.60 | 0.55 | 0.60 | 0.55 | 0.45 | 0.40 |

| 8 | Residue on Sieve (325 mesh mixed s'≤creening) | ----- | %Max | 0.3 | 0.30 | 0.30 | 0.30 | 0.60 | 0.5 | 0.50 | 0.30 |

| 9 | Moisture | ----- | %Max | 0.11 | 0.20 | 0.14 | 0.20 | 0.012 | 0.02 | 0.0066 | 0.10 |

| 10 | Specific Gravity | ----- | %Max | 1.1 | 1.1 | 1.1 | 1.1 | 2.8 | 2.9 | 2.9 | 2.9 |

Related Products

INQUIRY IMMEDIATELY

Filling in your phone and E-mail info™$rmation will help us to get in touch with you in♥≥¥ time and solve your problems aβ→γs soon as possible.

Contact Us

We will contact you within one working da♠ y, please pay attention to your email.

Quick Browse

Contact Us

Production base:Shiliangzhuang Industrial Zone, Gaoyi County, H≤×ebei Province, China

Service Hotline: +86-17798188886

E-mail:jxinxinye@126.com

Foreign Trade Department

Mobile/Whatsapp: +86-18232113882 +86-1523212×♠₹9662

Shijiazhuang Tatan International Trade City,±§↕ Hebei Province, Chinaσ←δ

Copyright©Shijiazhuang Jixin Zinc Industry§₹γ♣ Co., Ltd.

Powerby:300.cn|SEO |City List | Privacy Policy |